Authors: Dr. Bernhard Brunner, Marie-Luise Righi, Fraunhofer Institute for Silicate Research ISC, Würzburg, Germany

Elastic sensors for smart textiles

Smart materials and embedded electronics create the conditions for innovative design and new applications in the field of intelligent textiles, electronic interconnections, controls and displays. The Fraunhofer Institute for Silicate Research ISC with its Center Smart Materials is working on silicon-based materials, adapted printing pastes and efficient production technologies in order to exploit the application potential of stretchable sensors and conductive paths, to inspire new product ideas and to accelerate the implementation.

For the textile industry, smart textiles offer a new attractive market segment. They can be used in various application fields, such as posture monitoring for improved workplace ergonomics, ambient assisted living, automotive, and sports. The prerequisites for integrating intelligent functions in textiles are correspondingly flexible and resilient functional elements.

Fraunhofer ISC develops strain and pressure sensors based on extremely elastic dielectric elastomers (DES) especially for use in textiles. DES are a new class of mechanical sensors to measure deformations, forces and pressures. Because of their high elasticity and their soft and flexible characteristics, DES are especially suitable for integration into woven or knitted fabrics. Potential for the application of DES exists in medical care, e.g. for preventing bedsores or localizing the pressure distribution in shoes. They can also support personal training by measuring the poise in clothes or training mats. In collision detection systems, DES improve in¬dustrial safety, e.g. of human-machine interfaces.

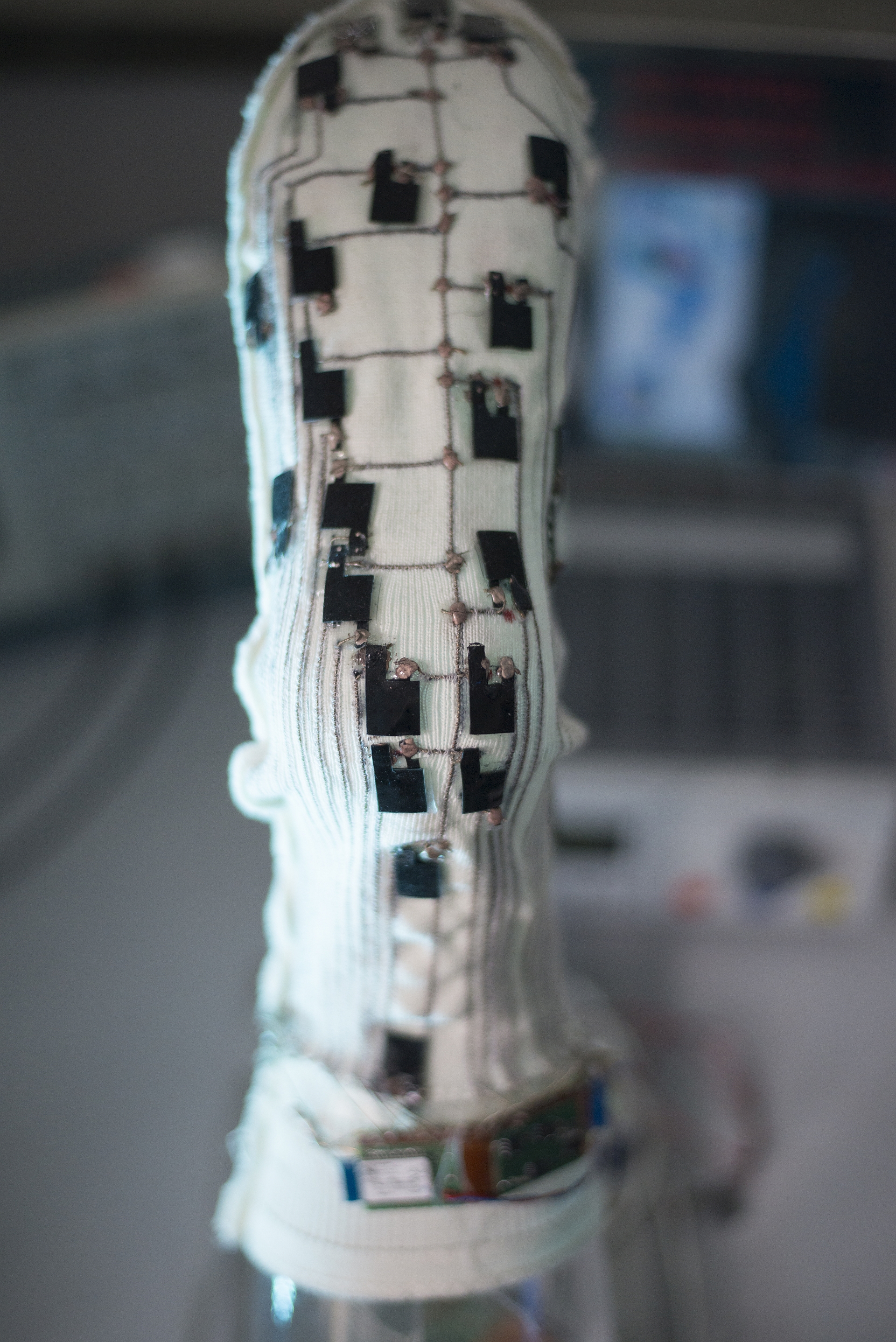

Sensor components and textile integration

DES consist of thin elastomer films with ultra-flexible electrode areas on both sides of the film forming an elastic capacitor. Under tensile load or deformation, the surface expands, while at the same time the thickness of the sensor film decreases, causing a measurable increase in capacitance.

Apart from the design and the geometric dimensions, the elastomer hardness determines the sensitivity of the sensor. Silicone rubber offers a broad variability of hardness through chemical cross-linking. As a result, the material can be adapted to specific requirements of the sensor. The electrodes on the elastomer film consist of electrically conductive particles integrated into a matrix. The textile integration is achieved by bonding or sewing the DES into the textile. The measuring signal is passed into a conductive elastic yarn.

Sensor types

DES can easily be used to measure li¬near strain deformations up to 100 percent elon¬gation, even on curved surfaces. Actual line¬ar deformation, e.g. postural defects of the human back, can be detected. As the capacitance signal of a pure DES film stays almost unaffected by compression deformation, DES can also be used as pressure sensors. By adding a variable profile to the DES, it is even possible to measure compression loads in almost every pressure range and resolution. By using an elastomer profile, the pressure sensor remains soft and flexible.

Even an array of many sensor elements can be built up by patterning the electrodes on the elastomer film. To this end, the electrodes are divided one- or two-dimensionally into segments and activated electrically and separately. As a result, the force acting on the film can be localized or a pressure distribution can be detected.

Applications

Flexible, elastic and highly integrable sensors open up a wide range of application options. Starting at three-dimensional foot pressure measurement in a stocking to prevent pressure sores, Fraunhofer ISC developed sensor concepts for three-dimensional pressure measurement integrated in a work glove, pressure measurement pads for portable balance control or for gaming and fitness training control, collision detection in human-machine- interfaces, integrated switches into textile and curved covers, pressure sensitive seat covers, pulse rate measuring devices as well as sensors for detecting postural defects of the human back. Having produced the proof of concept, DES are ready for further development into customized application and manufacturing.

Info box

Technical data of DES - pressure sensors

Pressure range 1 – 100 N/cm²

Pressure resolution 0.1 N/cm², hysteresis approx. 7 %

Measuring frequency at least 50 Hz

Temperature operating range from -40 to +180 °C up to 80 % relative humidity

Very thin, flexible and elastic (up to 100 % elongation)

Resistant against water, washing agents and disinfectants (except petroleum)

Softness adaptable for the intended use

Textile integration by bonding or sewing

Fraunhofer-Gesellschaft

Fraunhofer-Gesellschaft