Research Area TECHNICAL TEXTILES

VISION

New growth potential for the textile industry arises from the increasing demands on environmental and climate protection and the associated lightweight thinking, our inexhaustible need for comfort and functionality of textiles and the enormous potential for use as reinforcing material in building structures and other technical applications. Textile fibers and surfaces, individually and in hybrid composites, gradually replace conventional materials due to their outstanding properties.

Resource-efficient and sustainably manufactured with functional and smart properties, textiles are a guarantor for opening up new markets.

COOPERATION

The trend towards new technical textiles demands from companies an increasing need for innovation and research for the production of load-adapted or function-integrative textile structures, reproducible and in series.

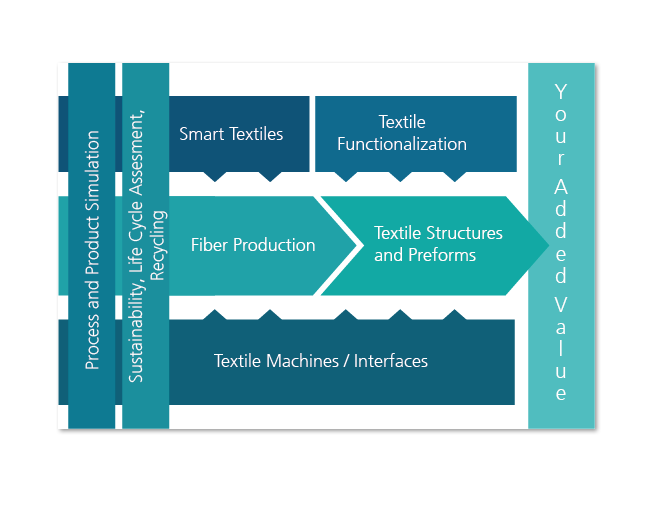

The Fraunhofer Institutes of the research area Technical Textiles work together in an interdisciplinary manner to generate optimal, application-specific, product-specific developments of textile-based technologies and plant systems.

TEAM

The Fraunhofer Institutes have teamed up in order to map the entire textile value creation chain from textile machinery, fiber production, preform and semi-finished product manufacture, textile functionalization, smart textiles, process and product simulation, sustainability - life cycle assessment and recycling, all the way to fiber composite components by bundling individual competences.

Dialogue creates the best solutions. Contact us!

Fraunhofer-Gesellschaft

Fraunhofer-Gesellschaft